713-645-1070

Specifications:

Materials of Construction:

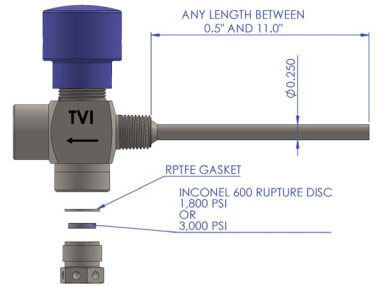

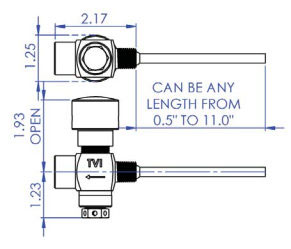

| Part Number | Rupture Disc | Outage Tube Length |

|---|---|---|

| TR-DVS-MF-OT-1800-X | X | X=Length in Inches |

| TR-DVS-MF-OT-3000-X | X | X=Length in Inches |

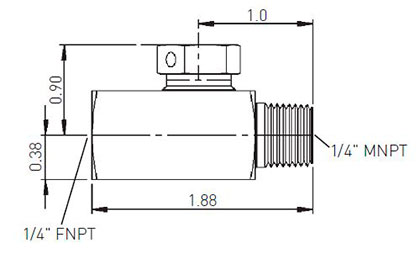

Rupture Disc Assembly

Part No. TR-RDT-A

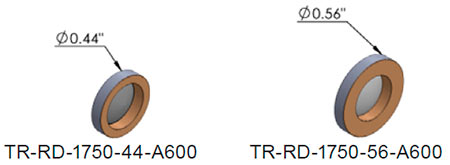

| Part No. | Burst Pressure | Diameter |

|---|---|---|

| TR-RD-1750-44-A600 | 1800 psi | 0.44 |

| TR-RD-1750-56-A600 | 1800 psi | 0.56 |

| TR-RD-2950-44-A600 | 3000 psi | 0.44 |

| TR-RD-2950-56-A600 | 3000 psi | 0.56 |

| TR-RD-5000-44-A600 | 5000 psi | 0.44 |

| TR-RD-5000-56-A600 | 5000 psi | 0.56 |

* FLAT RETAINER RING IS STANDARD

FITS MOST RUPTURE DISC HOLDER OF THE SAME DIAMETER

Can be use with a Teflon Gasket